The term “thermally broken” on an aluminum window is no guarantee of performance; many use cheap fillers that fail to prevent heat loss and can even cause frames to warp.

- High-quality breaks use glass-fiber reinforced polyamide (PA 6.6), not simple, ineffective resin.

- Poor thermal breaks cause a “bimetallic effect,” where dark-colored frames expand excessively in the sun and jam, a problem quality systems prevent.

Recommendation: Demand to see a frame cross-section and ask your supplier to specify the exact material and width of the thermal break before signing any contract.

You’ve been sold on the dream of sleek, modern aluminum windows. They offer slim profiles, durability, and a clean aesthetic that other materials can’t match. But you’ve also heard the horror stories: icy cold frames in winter, rampant condensation, and sky-high energy bills. The industry’s answer to this is the “thermally broken” frame. It’s the magic phrase every salesperson uses to reassure you. They’ll tell you a plastic insert separates the inside and outside metal, stopping the cold in its tracks.

But here is the uncomfortable truth they won’t tell you: not all thermal breaks are created equal. The market is flooded with windows that meet the bare-minimum definition of “thermally broken” but use cheap, inferior materials that offer little real-world benefit. A poorly designed thermal break is little more than marketing fluff, leaving you with a product that performs almost as badly as a solid aluminum frame. This is a deliberate ambiguity that profits manufacturers at your expense.

This guide takes a whistleblower’s approach. We will move beyond the sales pitch and arm you with the knowledge to act as your own quality inspector. You will learn to distinguish a high-performance, engineered polyamide component from a worthless resin filler. We will demystify U-values, uncover the hidden problem of thermal distortion that causes doors to jam, and show you precisely how to verify that the product you’re paying a premium for will actually deliver the comfort and efficiency you expect. It’s time to stop trusting the label and start verifying the facts.

This article provides an in-depth look into the critical components that determine the true performance of aluminum windows. We’ll break down the science and provide you with actionable verification methods, ensuring you can make an informed and secure investment in your home’s energy efficiency.

Summary: A Homeowner’s Guide to Verifying True Thermal Performance

- Why Solid Aluminum Frames Are Terrible for Energy Efficiency?

- How to Distinguish a High-End Polyamide Break from Cheap Resin?

- U-Value 1.4 vs 1.8: Is the Difference Worth the Extra Cost?

- The Distortion Problem That Jams Doors in Direct Sunlight

- How to Sit Next to a Large Window in Winter Without Feeling a Draft?

- Why Your Conservatory Loses Heat 4x Faster Than Your Living Room?

- Double vs Triple Glazing: Is the Extra Cost Worth It for a 3-Season Room?

- Why Floor-to-Ceiling Glass Walls Transform Small Rooms into Open Spaces?

Why Solid Aluminum Frames Are Terrible for Energy Efficiency?

Before the invention of the thermal break, aluminum windows were an energy efficiency nightmare. Aluminum is a fantastic conductor of heat—a property you want in a frying pan, not a window frame. A solid, non-broken aluminum frame acts as a thermal bridge, a superhighway for heat to escape your home in the winter and pour in during the summer. This isn’t a minor issue; it’s a fundamental flaw that can completely undermine the performance of even the most expensive double or triple-glazed glass unit. The frame becomes a weak link that bleeds energy and money.

The scale of this problem is staggering. According to window specialists, old-generation aluminum windows without thermal breaks can be responsible for up to 49% of a home’s heat loss in winter and a shocking 87% of its heat gain in summer. This is why a room with large, old aluminum windows feels impossible to keep warm or cool. The frame itself is actively working against your HVAC system, conducting outside temperatures directly into your living space. On a cold day, the interior surface of the frame will feel almost as cold as the outdoors, creating uncomfortable drafts and a prime surface for condensation and mold growth.

How can you spot these energy vampires? It’s simpler than you think. First, use the touch test on a cold day. Place your hand on the interior aluminum frame. If it feels intensely cold, you have a significant thermal bridge. Second, look for the evidence: chronic condensation, moisture, or even frost forming on the inside of the frame is a red flag for poor thermal performance. Finally, a visual inspection can sometimes reveal if the frame is a single, continuous piece of aluminum, the tell-tale sign of a non-broken, energy-wasting design.

How to Distinguish a High-End Polyamide Break from Cheap Resin?

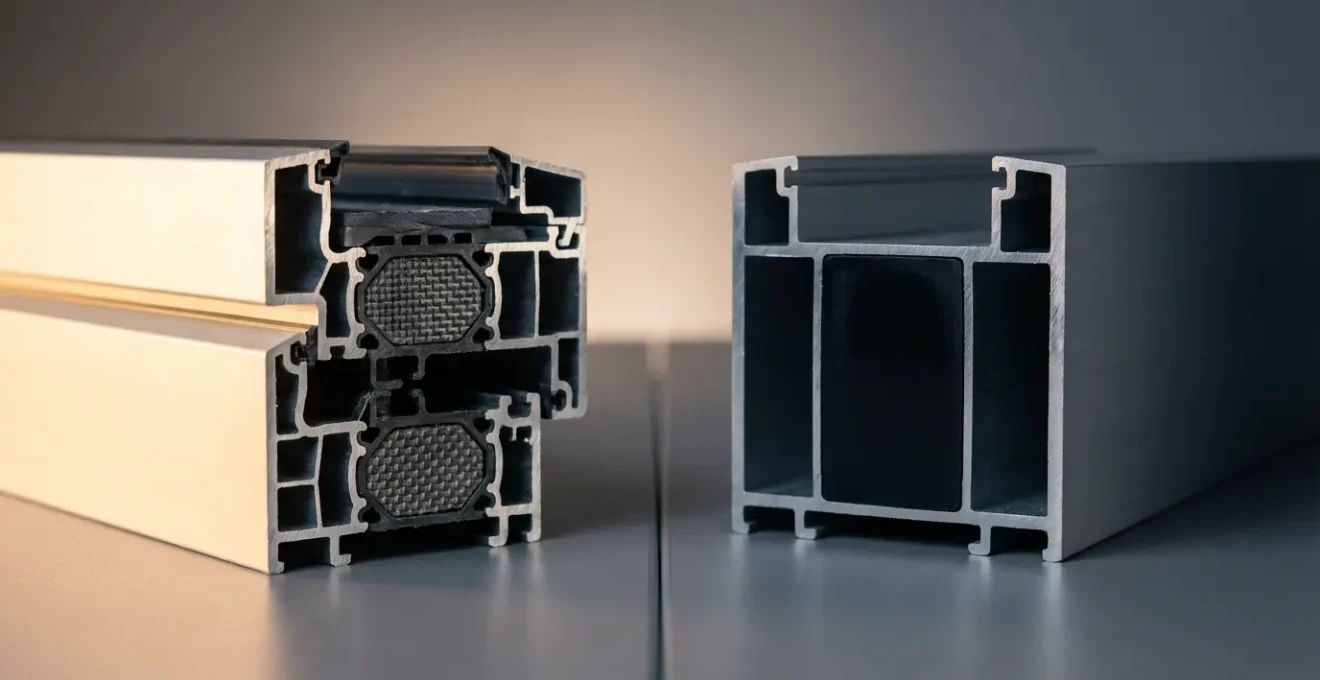

Here is the most critical secret the industry doesn’t want you to know: the word “thermally broken” means nothing without knowing *what* the break is made of. The performance difference between a quality thermal break and a cheap one is immense. A high-end frame uses a strut made of glass-fiber reinforced polyamide 6.6 (PA 6.6). This is an incredibly strong, stable, and low-conductivity engineering polymer designed to last for decades without becoming brittle. A cheap frame, by contrast, uses a simple resin or another inferior polymer that may offer some initial thermal resistance but can degrade, shrink, and lose its insulating properties over time.

Visually, the difference can be subtle without a cross-section, but the internal structure is night and day. A high-quality polyamide break often has multiple insulating chambers and a textured, matte finish from the glass fiber reinforcement. A cheap resin strip is typically a simple, solid piece of smooth plastic. Since you can’t see this once the window is installed, you must interrogate your supplier before you buy. The introduction of systems like ThermalHEART™ by AWS in 2007, which utilized these advanced polyamide strips, set a new benchmark for energy efficiency precisely because they focused on the quality of this core component.

As this comparison shows, the complexity and material science of a genuine polyamide break are far superior to a basic resin filler. To protect your investment, you must become an informed interrogator. Do not accept vague assurances. Use a checklist to demand specific, verifiable information from your potential supplier.

Your Supplier Interrogation Checklist: Verifying Thermal Break Quality

- Ask for the Material Spec: Ask directly, “Is the thermal break made from glass-fiber reinforced polyamide 6.6 (PA 6.6), or is it a standard resin or PVC?” Their hesitation is your answer.

- Request a Sample: Demand to see a physical cross-section of the frame. A proud manufacturer will have these readily available. Look for internal chambers within the break.

- Verify the Dimensions: Ask, “What is the width of the thermal break in millimeters, and how many chambers does it contain?” A wider, multi-chambered break is exponentially better.

- Question its Longevity: Inquire about material stability: “What is the expected lifespan of the break before it becomes brittle?” Quality polyamide maintains its flexibility and integrity for over 25 years.

U-Value 1.4 vs 1.8: Is the Difference Worth the Extra Cost?

Once you’ve verified the quality of the thermal break material, the conversation shifts to performance metrics, specifically the U-value (or U-factor). The U-value measures how well a window prevents heat from escaping. The lower the U-value, the better its insulating performance. A thermal break is the single most effective technology for lowering an aluminum window’s U-value. Data based on NFRC standards shows that incorporating a proper thermal break can slash a typical aluminum frame’s U-factor from around 2.0 down to 1.0 Btu/hr-sq or even lower, effectively cutting heat loss through the frame by 50% or more.

But when you’re comparing two good, thermally broken windows, you might be faced with a choice between a U-value of 1.8 and 1.4. Is the extra cost for that 0.4 difference justified? The answer is an emphatic yes, especially for large windows or colder climates. A U-value of 1.8 is decent, but a U-value of 1.4 represents a significant leap in performance. This isn’t just a number on a sticker; it translates directly to two things: your comfort and your energy bills. With a 1.4 U-value window, the interior surface of the glass and frame will be noticeably warmer in winter, eliminating cold drafts and allowing you to comfortably sit right next to the window.

While the upfront cost is higher, the long-term savings are real. The payback period for upgrading from a mediocre to a high-performance U-value is often between 5 to 8 years through reduced heating and cooling costs. The table below illustrates the tangible differences.

| U-Value | Annual Energy Cost (Large Window) | Payback Period | Interior Surface Temp (0°C outside) |

|---|---|---|---|

| 1.4 | Lower baseline | 5-8 years | Significantly warmer |

| 1.8 | +20-30% higher | N/A | Noticeably cooler |

The Distortion Problem That Jams Doors in Direct Sunlight

Here’s a problem that affects owners of low-quality thermally broken windows and doors, especially those with dark-colored frames: the door that works perfectly in the morning gets stuck or becomes difficult to lock in the afternoon sun. This isn’t a faulty lock; it’s a physics problem called thermal bowing or the “bimetallic effect.” It happens when the exterior aluminum profile, baking in direct sunlight, heats up and expands significantly, while the interior profile remains cool in your air-conditioned room. If the thermal break connecting them is not robust enough to manage this differential movement, the entire frame can warp or bow.

A high-quality, reinforced polyamide thermal break does more than just stop heat transfer; it acts as a crucial expansion joint. It’s engineered to be strong yet flexible enough to absorb the stress between the expanding outer frame and the stable inner frame, preventing distortion. This is where cheap resin breaks completely fail. They are too rigid and can’t manage the forces, leading to operational problems. The impact of a good break is massive; by inserting a quality polyamide bar, a window can slow down the transfer of heat by up to 1,000 times compared to a non-broken frame, which directly reduces the severity of this bimetallic effect.

This issue is particularly severe with popular dark colors like anthracite grey or black, as they absorb far more solar radiation. If you are planning to use dark frames, especially on a south or west-facing elevation, specifying a superior thermal break system is not a luxury—it’s an absolute necessity to ensure long-term functionality. Before purchasing, you should specifically ask for thermal bowing test data for the color you’ve chosen. Insist on a wider thermal break (at least 24mm) and verify that the polyamide strips are reinforced and rated for the temperature extremes of your local climate.

How to Sit Next to a Large Window in Winter Without Feeling a Draft?

The ultimate test of a window’s performance isn’t a number on a sticker, but a feeling: can you sit comfortably next to a huge pane of glass on a freezing winter day without feeling a chill? With a standard or poorly broken aluminum frame, the answer is no. You feel a constant “cold draft,” which isn’t actually moving air but rather your own body heat radiating towards the cold surface of the glass and frame. This radiant heat loss makes you feel cold and forces you to crank up the thermostat, even if the room’s air temperature is technically warm.

A high-performance, thermally broken aluminum window completely changes this dynamic. The combination of a top-tier polyamide break and high-performance glazing (like low-E coated double or triple glazing) works to keep the interior surface temperature of the window close to the room’s air temperature. When the surface isn’t cold, you don’t lose your body heat to it. The “draft” disappears, and you can place your favorite armchair right by the window, creating a cozy, light-filled nook to enjoy the winter scenery in total comfort. This is the true meaning of thermal comfort.

You can even verify this effect yourself with a simple, affordable tool. An infrared thermometer gun (often under $50) can reveal the truth about a window’s performance. On a cold day, point it at the center of the glass, then at the edge of the glass near the frame, and finally at the frame itself. In a high-performance window, all three temperatures will be very close to each other (within 2-3°C). In a poorly performing window, you’ll see a dramatic temperature drop of 5°C or more at the edges and on the frame, exposing the thermal bridges that are stealing your comfort and your money.

Why Your Conservatory Loses Heat 4x Faster Than Your Living Room?

If you’ve ever owned a traditional conservatory with aluminum framing, you know it’s a room of extremes: a sauna in the summer and an icebox in the winter. Why does it perform so much worse than a normal room in your house? The answer lies in two factors: exposed surface area and thermal bridges. A typical living room has only one exposed surface (the wall with the window). A conservatory has at least five: four walls and a roof, all largely made of glass and framing. This exponentially increases the area for heat to escape.

Now, combine this massive surface area with a material like standard aluminum. Analysis of thermal properties reveals that aluminum conducts heat at over 1,000 times the rate of wood or vinyl (uPVC). When you build a five-sided structure out of it, you’ve essentially created a giant, inefficient radiator that works in reverse, dumping your precious heat into the cold winter air. Studies on building efficiency have shown that these thermal bridges are not a minor detail; they are the direct cause of about 30% of energy waste in buildings.

This is precisely why modern, high-performance thermally broken aluminum systems are the key to transforming these spaces. By incorporating a robust polyamide break into every frame and rafter of the conservatory, you sever those thermal bridges. You turn the structure from an energy sieve into a properly insulated enclosure. This is what makes the difference between a “three-season room” that’s unusable for five months of the year and a true, year-round “garden room” or extension of your living space. Without a top-quality thermal break, you are simply throwing money away trying to heat a space that is structurally designed to lose it.

Double vs Triple Glazing: Is the Extra Cost Worth It for a 3-Season Room?

When planning a conservatory or a “3-season room,” the focus is often on the glass. The debate between double and triple glazing is common, with many assuming “more is always better.” However, for a space that is not intended to be a primary, full-time living area through the harshest part of winter, this assumption can be a costly mistake. For a 3-season room, the primary goal is to extend its usability into the cooler spring and autumn months and to prevent overheating in the summer—not necessarily to maintain a perfect 21°C when it’s -10°C outside.

In this specific context, a high-quality double-glazing unit often represents the smarter investment. The reason lies in Solar Heat Gain. A good double-glazing unit allows more of the sun’s warming rays to enter the room, which is a significant benefit during cool, sunny days in spring and autumn, providing “free” heat. Triple-glazing, designed for maximum insulation, blocks more of this beneficial solar gain. While it offers a superior U-value (better at stopping heat loss), the significant cost premium of 40-60% is very difficult to justify for a room that isn’t used as a primary living space in deep winter. The one exception is acoustics; if the room is near a noisy road, the extra layer of glass in a triple-glazed unit provides excellent sound insulation.

This balanced approach is confirmed by experts in the field. As one leading guide on energy-efficient windows notes:

For a 3-season room, the goal is to prevent chill, not to fight deep frost. The best choice is often a high-quality double-glazing unit with a balanced U-value and a moderate-to-high Solar Heat Gain Coefficient.

– Building Science Expert, Energy Efficient Windows Guide

The verdict is clear: for a 3-season room, invest your budget first in a superior thermally broken aluminum frame, and pair it with a high-performance double-glazing unit. This combination will provide the best balance of comfort, cost, and energy performance for the room’s intended use.

Key Takeaways

- The term “thermally broken” is meaningless without verifying the break material; insist on glass-fiber reinforced polyamide (PA 6.6).

- Poor thermal breaks in dark-colored frames can cause thermal bowing (the bimetallic effect), leading to warped frames and jamming doors.

- A lower U-value (e.g., 1.4 vs. 1.8) significantly improves comfort by raising the window’s interior surface temperature, which is worth the investment.

Why Floor-to-Ceiling Glass Walls Transform Small Rooms into Open Spaces?

The architectural dream of the “invisible wall”—a floor-to-ceiling expanse of glass that seamlessly merges indoor and outdoor spaces—is one of the most compelling reasons to choose aluminum. No other common frame material has the structural strength-to-size ratio to make this possible. The inherent strength of aluminum allows for incredibly slim, sleek profiles that can support enormous panes of glass. This maximizes the view and floods a room with abundant natural light, making even small rooms feel vast, open, and connected to the landscape.

However, for decades, this architectural ambition came with a harsh, practical penalty: abysmal energy performance. A wall of glass framed in standard aluminum was a thermal disaster. This is where the modern, high-performance thermally broken system becomes the hero of the story. It finally bridges the gap between architectural aspiration and practical, comfortable reality. By integrating a robust polyamide thermal break, manufacturers can now offer the same slim profiles and minimalist sightlines without compromising on thermal comfort.

This technology is what truly enables the transformation. It ensures that the massive glass wall does not become a massive cold spot in winter or an overwhelming heat source in summer. As noted by industry leaders, the sleek profile of aluminum allows for larger panes of glass, and the thermal break ensures this design choice is viable in all climates. It allows architects and homeowners to pursue bold designs without being penalized with an uncomfortable home and exorbitant energy bills. The result is a space that not only looks spectacular but also feels comfortable and livable year-round, truly transforming the perception and function of a room.

Now armed with this knowledge, you are no longer a passive buyer but an active inspector. Do not be swayed by marketing jargon. Demand specifics, request samples, and question everything. Your investment is not just in a window, but in the long-term comfort, efficiency, and functionality of your home.